So I took my accuracy systems inc armalite style upper out yesterday to the range. After 100ish rounds I found 3 pierced primers. I was shooting 7.62x51 175 gr lake city mil surp. I. Have enclosed some pictures to show you all what I'm dealing with. Put a call in to ASI and waiting for the boss to call me back on Wednesday as he is out of the office until then. Any ideas?

JoeyPBasically

Ar-10 piercing primers help

JoeyPBasically

Discussion starter

77 posts

·

Joined 2013

- Add to quote Only show this user

So I took my accuracy systems inc armalite style upper out yesterday to the range. After 100ish rounds I found 3 pierced primers. I was shooting 7.62x51 175 gr lake city mil surp. I. Have enclosed some pictures to show you all what I'm dealing with. Put a call in to ASI and waiting for the boss to call me back on Wednesday as he is out of the office until then. Any ideas?

Attachments

-

101.4 KB Views: 380

-

89 KB Views: 160

-

99.5 KB Views: 162

-

96.2 KB Views: 179

-

95.8 KB Views: 151

JoeyPBasically

Discussion starter

77 posts

·

Joined 2013

JoeyPBasically

Discussion starter

77 posts

·

Joined 2013

I built the lower with an iron ridge billet lower and a national match armalite lower parts kit, the upper was completely built by ASI. The entire rifle is custom for the most part. What effect would the trigger have on this?

1,456 posts

·

Joined 2013

imney

I would like to know what kind of trigger, 2 stage ? I had a similar problem after I put a Timney in a similar rifle, the firing pin was blastic thru the primer caps, and another rifle the primers were not getting hit hard enough.I put the stock trigger back in and had no more problems. you may want to change the firing pin first......Also try using different ammo and see what happens although military primers are much harder than civilian.

I would like to know what kind of trigger, 2 stage ? I had a similar problem after I put a Timney in a similar rifle, the firing pin was blastic thru the primer caps, and another rifle the primers were not getting hit hard enough.I put the stock trigger back in and had no more problems. you may want to change the firing pin first......Also try using different ammo and see what happens although military primers are much harder than civilian.

8,557 posts

·

Joined 2012

My initial guess is it is the ammo. After looking at the pictures of the cases it seems they are showing pressure signs, the really shined mark where the ejector imprinted itself. Try to shoot some Other commercial ammo and see if it still does it. Some Federal Gold Metal match 168 stuff if you can fins any.

3,481 posts

·

Joined 2013

I agree with dsdmmat. The firing pin is not piercing the primer. You are having overpressure causing the primer to flow around the firing pin. You can see the ejector imprinting on the back end of the brass. I would buy some factory ammo and do some shooting to see if the problem moves WITH the gun or with the ammo.

JoeyPBasically

Discussion starter

77 posts

·

Joined 2013

The firing pin definetly needs replacing at this point though no?

2,126 posts

·

Joined 2013

Firing pin must be replaced as it is damaged. Check also the spring for the pin.

9,955 posts

·

Joined 2013

How cleaned/lubed is the carrier group? Is the firing pin free floating or does it hang up and stick? Does the firing pin movement seem sluggish? Is the firing pin bent along the overall length? Any slam fires?

JoeyPBasically

Discussion starter

77 posts

·

Joined 2013

Very clean and frog lubed, the pin started free floating but as the pierces happened, primer pieces went into the firing pin port making it slow down. Had 2 no fires, no slam fires or pre detonations.

firing pin seems to have a nick in it, I tried to get a good picture of it above.

firing pin seems to have a nick in it, I tried to get a good picture of it above.

11,402 posts

·

Joined 2010

you have two factors. A) hot ammo. B) Potentially a firing pin protruding in excess that should not be less than 0.025" or more than 0.035".

you can check this with a caliper or gauge. Make sure everything is super clean to measure w/o debirs.

If this is the problem it is easy to fix. You just need to very slowly remove the excess.

you can check this with a caliper or gauge. Make sure everything is super clean to measure w/o debirs.

If this is the problem it is easy to fix. You just need to very slowly remove the excess.

7,703 posts

·

Joined 2010

Looks like a bunch of cosmoline in there to me, not saying that's the problem but....

1,430 posts

·

Joined 2011

I highly doubt that LC ammo is over pressured, first thing I'd do is have the headspace checked.

11,402 posts

·

Joined 2010

Why would anyone think they are over-pressure? They are hot military loads as per the Lake City NATO head stamp.

If the op can check the side of the cases looking some stretching then it is a sign but primers look fine other than the piercing.

Always chamber clean and dry of oil and debris. Also specially important to use gauges and measure.

Also if you had two misfires can you check the primers and cases? Compare a round from this batch with one fired. With the calipers

is easy measuring and take a delta reading from the datum (shoulder) of the case. If you do not have a gauge use a larger case caliber and compare.

If you have a HS gauge go and do the no go headspace although an Armalite factory rifle should be fine.

All things have to check ok. Don't discard this could be an ammo issue with the surplus.

If the op can check the side of the cases looking some stretching then it is a sign but primers look fine other than the piercing.

Always chamber clean and dry of oil and debris. Also specially important to use gauges and measure.

Also if you had two misfires can you check the primers and cases? Compare a round from this batch with one fired. With the calipers

is easy measuring and take a delta reading from the datum (shoulder) of the case. If you do not have a gauge use a larger case caliber and compare.

If you have a HS gauge go and do the no go headspace although an Armalite factory rifle should be fine.

All things have to check ok. Don't discard this could be an ammo issue with the surplus.

1,430 posts

·

Joined 2011

You also need to clean out all that lube, way too much and it may be making it's way into the chamber. Make damn sure it's not getting into the chamber, the chamber should be free of all lube. You've got a lot of little pieces of brass that's sticking to the lube, see the chunks stuck to the face of your bolt? Probably also inside the barrel extension around the locking lugs that you can't see, I'd get a lug cleaning tool to clean the extension out, like this --> http://www.brownells.com/gun-cleani...leaning-kit-accessories/sinclair-ar-15-and-ar-10-lug-recess-tool-prod34907.aspx

I've got one of those (new) for the AR10 I'd cut you a deal on, you'll have to buy the cotton rolls, I only have a few.

I've got one of those (new) for the AR10 I'd cut you a deal on, you'll have to buy the cotton rolls, I only have a few.

JoeyPBasically

Discussion starter

77 posts

·

Joined 2013

This is a custom built rifle, not a stock armalite. Only thing made by armalite on this rifle is the stripped upper receiver and the lower parts kit. The upper was made by Accuracy Systems Inc. I built the lower using an iron ridge billet lower and a armalite national match grade parts kit. I don't think frog lube would cause pierced primers. I have a feeling my gun either doesn't like this ammo, the firing pin/port is off, or possibly the headspace. But I feel like a headspace issue would of cause far more problems.

11,402 posts

·

Joined 2010

You welcome. This is our job to see if we can help each other.

The headspace in 7.62x51 has larger tolerances and even if it was on the large side the brass is designed to take it w/o any issues.

The only problem here is with very old military chambers like found in surplus FAL and even some early M14's / M1A converted that some folks found didn't pass the field gauge check or otherwise found out the hard way if you know what i mean.

Also an upper built by Accuracy Ssytem shoud be dead on. I mean you can try for your own peace of mind but I am sure that is not

the problem. however measure the firing pin protrusion and don't discard the ammo problems. I had batches of expensive Match Ammo

factory new blowing off primers. so imagine military surplus. Something very rare but it happends.

Again measure the protrusion.

The headspace in 7.62x51 has larger tolerances and even if it was on the large side the brass is designed to take it w/o any issues.

The only problem here is with very old military chambers like found in surplus FAL and even some early M14's / M1A converted that some folks found didn't pass the field gauge check or otherwise found out the hard way if you know what i mean.

Also an upper built by Accuracy Ssytem shoud be dead on. I mean you can try for your own peace of mind but I am sure that is not

the problem. however measure the firing pin protrusion and don't discard the ammo problems. I had batches of expensive Match Ammo

factory new blowing off primers. so imagine military surplus. Something very rare but it happends.

Again measure the protrusion.

JoeyPBasically

Discussion starter

77 posts

·

Joined 2013

The cases didn't appear to have any stress marks on the sides.

also thank you everyone for your input so far! I really appreciate it. Nothing more stressful than when your expensive rifle fails. Rifle isn't brand new but has only been taken out 4-5 time with a maximum round count of 400 through it.

also thank you everyone for your input so far! I really appreciate it. Nothing more stressful than when your expensive rifle fails. Rifle isn't brand new but has only been taken out 4-5 time with a maximum round count of 400 through it.

11,402 posts

·

Joined 2010

There is no such thing as a gun hatting ammo. It can be more accurate or less accurate but there is something that is different and the explanation to your issue could be simple.

check the protrusion. What if the problem is the bolt OAL? Don't need to replace the pin although it is a good idea to keep a spare with you.

check the protrusion. What if the problem is the bolt OAL? Don't need to replace the pin although it is a good idea to keep a spare with you.

JoeyPBasically

Discussion starter

77 posts

·

Joined 2013

I think my firing pin is the main cause or atleast has been deformed by this batch of ammo. Either way I'm waiting for ASI to call me back and see if they can sell me a new firing pin, since their bcg is custom to their uppers. And I'll prob sell this ammo my friend with the savage for cheap as he just got his gun and it worked fine for him. If you look at the firing pin picture it definitely has a nick of sorts in it.

![]()

11,402 posts

·

Joined 2010

Again, put the firing pin back and measure the protrusion holding the ping against the bolt.I think my firing pin is the main cause or atleast has been deformed by this batch of ammo. Either way I'm waiting for ASI to call me back and see if they can sell me a new firing pin, since their bcg is custom to their uppers. And I'll prob sell this ammo my friend with the savage for cheap as he just got his gun and it worked fine for him. If you look at the firing pin picture it definitely has a nick of sorts in it. View attachment 35315

That is the way to find out.

The pin needs to stop at the back end stop and if doesn't then eventually will protrude even more.

This means the end of the pin (like the hat on a man) will stop at the mouth of the bolt when hit

by the hammer. If you see any gaps there you have to assume the pin stops at the taper in the

tip then eventually the pin might set squeezed in the firing pin hole and further into the primers.

So measure! ... that is the first thing I advised on my first post.

JoeyPBasically

Discussion starter

77 posts

·

Joined 2013

How exactly can I measure this with calipers?

11,402 posts

·

Joined 2010

you can do two things.

A) Cut a gauge using a piece of steel. you can make the maximum as a square cut (Female slot).

Might be able to do this with a small file and where the back end of the caliper rail (depth probe) can fit.

You can make a thin rod and have the max on one side and the min on the other althoug the minimum

in this case is not going to be your problem that most times is failure to ignite the primer and therfire

failure to fire.

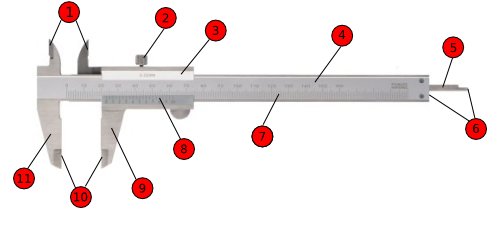

Depth probe is nr. 5 on this graphic.

Parts of the Vernier Caliper

![Image]()

The metal part must fit inside the bolt's head. Then when pushing the pin it must go into the slot but should not touch

nor push the gauge you just made.

This is different firearm but it will give you and idea of what a simple metal gauge should do....

B) Use the depth probe. Since you have to measure from the face of the bolt and the back end of the capliper will not go

into the recess of the bolt you have to make a reading first from the edge of the bolt (ring around the AR bolt lugs)

or there reset your caliper to zero. then close the bolt and push the pin against the bolt so it protrudes to the maximum

so now you can take a reading with the caliper again but the depth probe touching the pin. The trick here is since the pin

is round make sure the probe stays on the very tip of the pin and doesn't slide down.

In the below video, this is what this extension is for. It migrates the protrusion to a bushing that fits inside recessed bolts like the AR and it is also flat so it can simply measured w/o slipping off and angle errors. but my take you do not need it. The caliper alone should be able to do it.

Once you measure your protrusion you will know if this is the problem or you can discard this. but to me this is going to

be the issue. Also remember the AR pin must stop at the back of the pin (large ring) and hit the carrier there and not the taper int he tip of the pin.

Good luck.

A) Cut a gauge using a piece of steel. you can make the maximum as a square cut (Female slot).

Might be able to do this with a small file and where the back end of the caliper rail (depth probe) can fit.

You can make a thin rod and have the max on one side and the min on the other althoug the minimum

in this case is not going to be your problem that most times is failure to ignite the primer and therfire

failure to fire.

Depth probe is nr. 5 on this graphic.

Parts of the Vernier Caliper

The metal part must fit inside the bolt's head. Then when pushing the pin it must go into the slot but should not touch

nor push the gauge you just made.

This is different firearm but it will give you and idea of what a simple metal gauge should do....

B) Use the depth probe. Since you have to measure from the face of the bolt and the back end of the capliper will not go

into the recess of the bolt you have to make a reading first from the edge of the bolt (ring around the AR bolt lugs)

or there reset your caliper to zero. then close the bolt and push the pin against the bolt so it protrudes to the maximum

so now you can take a reading with the caliper again but the depth probe touching the pin. The trick here is since the pin

is round make sure the probe stays on the very tip of the pin and doesn't slide down.

In the below video, this is what this extension is for. It migrates the protrusion to a bushing that fits inside recessed bolts like the AR and it is also flat so it can simply measured w/o slipping off and angle errors. but my take you do not need it. The caliper alone should be able to do it.

Once you measure your protrusion you will know if this is the problem or you can discard this. but to me this is going to

be the issue. Also remember the AR pin must stop at the back of the pin (large ring) and hit the carrier there and not the taper int he tip of the pin.

Good luck.

JoeyPBasically

Discussion starter

77 posts

·

Joined 2013

Also noticed this the back end of the pin is showing deformation

Attachments

-

100.6 KB Views: 165

11,402 posts

·

Joined 2010

This is where the hammer hits. Some signs of wear are normal but not flat burrs.

So this might be an example of a firing pin is not properly heat treated (hardened) or the wrong material or both and one could suspect wrong dimensions too.

Buy one firing pin from Armalite (if that is your bolt I would assume with AR10 system right?). don't interchange with other brands from who knows what mills and treatments. Specially don't interchange with other makers of different 308 systems even if they look similar. Unlike the AR15 there is no one single standard for parts.

Also I noticed this doesn't look like an AR10 firing pin. The AR10 is tapered and it has a spring. Are you sure you have an AR10 and not a DPMS or RRA upper? who built this upper again?

![Image]()

AR-10 FIRING PIN

Spring. (designed to minimize the risk of slam fires).

![Image]()

AR-10 FIRING PIN SPRING

So this might be an example of a firing pin is not properly heat treated (hardened) or the wrong material or both and one could suspect wrong dimensions too.

Buy one firing pin from Armalite (if that is your bolt I would assume with AR10 system right?). don't interchange with other brands from who knows what mills and treatments. Specially don't interchange with other makers of different 308 systems even if they look similar. Unlike the AR15 there is no one single standard for parts.

Also I noticed this doesn't look like an AR10 firing pin. The AR10 is tapered and it has a spring. Are you sure you have an AR10 and not a DPMS or RRA upper? who built this upper again?

AR-10 FIRING PIN

Spring. (designed to minimize the risk of slam fires).

AR-10 FIRING PIN SPRING

11,402 posts

·

Joined 2010

Actually I can measure a firing pin for you if you want but it would be Stoner SR25/Knigths/DPMS type of system not AR10.

I think RRA might be using the same firing pin but not 100% sure.

I think RRA might be using the same firing pin but not 100% sure.

JoeyPBasically

Discussion starter

77 posts

·

Joined 2013

Well I was hoping I wouldn't but I'm sending the rifle back to Colorado to have it checked out by ASI . Let's hope the turnaround is fast.

1,430 posts

·

Joined 2011

I think that's a wise choice, I'd send some of those fired cases with it as well. Hope you get her back quick and running like a clock!

11,402 posts

·

Joined 2010

Do you have a set of calipers? Before you send it can you measure the firing pin just o satisfy our curiosity?

Lenght...

Back to the pin stop...

diameter at the rear end..

diameter at the head...

you never mesured the protrusion did you?

I will measure a knights firing pin and we can compare.

Lenght...

Back to the pin stop...

diameter at the rear end..

diameter at the head...

you never mesured the protrusion did you?

I will measure a knights firing pin and we can compare.

11,402 posts

·

Joined 2010

According to the OP and the pics there isn't any kind of over-pressure anywhere and those signs they always come in twos and threes.

No extrusion marks, no flat primers, no swelling, no streching. Just the ejector mark indicates a proper ejection curve.

Those are hot loads nothing else. how do we know they are hot, well they are LC 07 and they are loaded close to max pressure.

My money goes to the firing pin. The op did the right thing as he doesn't have the gauges, tools,etc.. to fix this. ASI will make it right.

The sad part we might never know the cause, or maybe they will give the real reason when the rifle is back.

Keep us posted.

No extrusion marks, no flat primers, no swelling, no streching. Just the ejector mark indicates a proper ejection curve.

Those are hot loads nothing else. how do we know they are hot, well they are LC 07 and they are loaded close to max pressure.

My money goes to the firing pin. The op did the right thing as he doesn't have the gauges, tools,etc.. to fix this. ASI will make it right.

The sad part we might never know the cause, or maybe they will give the real reason when the rifle is back.

Keep us posted.

1,430 posts

·

Joined 2011

Guys I really don't care, a brother asked for some help, I wasn't looking for a contest. The important thing is Joey will get his problems resolved.

2,650 posts

·

Joined 2013

Agreed, and I think your headspace theory has some merit, just have not seen it personally. Let us know how you make out JoeyPBasically.

JoeyPBasically

Discussion starter

77 posts

·

Joined 2013

I appreciate everyone's help. I'm confident ASI will give me the full diagnosis and I will definitely report back once they do.

JoeyPBasically

Discussion starter

77 posts

·

Joined 2013

Ok so Carl from ASI called today my rifle arrived this morning. The firing pin is def deformed beyond use. He also said my bcg looked as if is put thousands of rounds through the gun.... I have only put 400-500 Max since I built it in 2012, so we're pretty sure that it was the ammo since that lake city 175gr surplus 7.62x51 was about 90% of those rounds. Headspace was perfect and it test fired fine with 308 ammo. Also found out that although my gun is armalite upper and lower... It has a dpms bcg which I believe he said they retrofitted to my gun when building it. Said the lugs on my bcg looked polished that's how much wear there was.... Could all this of been caused by using this 7.62x51 surplus? Anyway he's sending it back with a new firing pin and I may just pick up a back up bcg to be safe. Any thoughts?

11,402 posts

·

Joined 2010

Discoloration in the lugs is normal form use. the parkerizing goes away. Make sure you lube them a bit. I put a microscopic amount of oil

or grease. same thing with the cam pin, camp pin head and other critical parts. Just do not over lube. can use the dry lube too but I prefer wet.

So it was a dpms BCG after all. All this to change the firing pin. If the firing pin has the proper protrusion and it is a good quality one I would doubt

you will ever have any issues with any kind of ammo. If they didn't measure the protrusion then you might have the issues again.

Also as we suspected the headspace was fine.

But Wow this guy is fast!

...just like FN or Beretta who keep their civilian repairs for months at the time.

or grease. same thing with the cam pin, camp pin head and other critical parts. Just do not over lube. can use the dry lube too but I prefer wet.

So it was a dpms BCG after all. All this to change the firing pin. If the firing pin has the proper protrusion and it is a good quality one I would doubt

you will ever have any issues with any kind of ammo. If they didn't measure the protrusion then you might have the issues again.

Also as we suspected the headspace was fine.

But Wow this guy is fast!

...just like FN or Beretta who keep their civilian repairs for months at the time.

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 1.3M

- members

- 19K

- Since

- 2008

A forum community dedicated to all New York firearm owners and enthusiasts. Come join the discussion about optics, hunting, gunsmithing, styles, reviews, accessories, classifieds, and more!