So I took my accuracy systems inc armalite style upper out yesterday to the range. After 100ish rounds I found 3 pierced primers. I was shooting 7.62x51 175 gr lake city mil surp. I. Have enclosed some pictures to show you all what I'm dealing with. Put a call in to ASI and waiting for the boss to call me back on Wednesday as he is out of the office until then. Any ideas?

Ar-10 piercing primers help

JoeyPBasically

21 - 40 of 70 Posts

Joined

·

77 Posts

Yeah ah my buddies savage bolt was firing these no problem. Which makes me believe that my gun hates this ammo, or the firing pin was protruding to much. Either way my firing pin has a nick in it and will need to be replaced. I also can't imagine headspace being the issue as it's only been these 3 rounds out of 400+ And ASI is known for their quality and the rifle shoots 1/2" groups at 200 yards if I'm patient enough. I just don't wanna blow up or blow anyone else up on accident.You welcome. This is our job to see if we can help each other.

The headspace in 7.62x51 has larger tolerances and even if it was on the large side the brass is designed to take it w/o any issues.

The only problem here is with very old military chambers like found in surplus FAL and even some early M14's / M1A converted that some folks found didn't pass the field gauge check or otherwise found out the hard way if you know what i mean.

Also an upper built by Accuracy Ssytem shoud be dead on. I mean you can try for your own peace of mind but I am sure that is not

the problem. however measure the firing pin protrusion and don't discard the ammo problems. I had batches of expensive Match Ammo

factory new blowing off primers. so imagine military surplus. Something very rare but it happends.

Again measure the protrusion.

Joined

·

11,402 Posts

There is no such thing as a gun hatting ammo. It can be more accurate or less accurate but there is something that is different and the explanation to your issue could be simple.

check the protrusion. What if the problem is the bolt OAL? Don't need to replace the pin although it is a good idea to keep a spare with you.

check the protrusion. What if the problem is the bolt OAL? Don't need to replace the pin although it is a good idea to keep a spare with you.

Joined

·

77 Posts

I think my firing pin is the main cause or atleast has been deformed by this batch of ammo. Either way I'm waiting for ASI to call me back and see if they can sell me a new firing pin, since their bcg is custom to their uppers. And I'll prob sell this ammo my friend with the savage for cheap as he just got his gun and it worked fine for him. If you look at the firing pin picture it definitely has a nick of sorts in it.

![]()

Joined

·

11,402 Posts

Again, put the firing pin back and measure the protrusion holding the ping against the bolt.I think my firing pin is the main cause or atleast has been deformed by this batch of ammo. Either way I'm waiting for ASI to call me back and see if they can sell me a new firing pin, since their bcg is custom to their uppers. And I'll prob sell this ammo my friend with the savage for cheap as he just got his gun and it worked fine for him. If you look at the firing pin picture it definitely has a nick of sorts in it. View attachment 35315

That is the way to find out.

The pin needs to stop at the back end stop and if doesn't then eventually will protrude even more.

This means the end of the pin (like the hat on a man) will stop at the mouth of the bolt when hit

by the hammer. If you see any gaps there you have to assume the pin stops at the taper in the

tip then eventually the pin might set squeezed in the firing pin hole and further into the primers.

So measure! ... that is the first thing I advised on my first post.

Joined

·

77 Posts

How exactly can I measure this with calipers?

Joined

·

11,402 Posts

you can do two things.

A) Cut a gauge using a piece of steel. you can make the maximum as a square cut (Female slot).

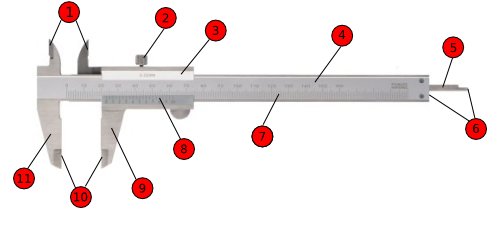

Might be able to do this with a small file and where the back end of the caliper rail (depth probe) can fit.

You can make a thin rod and have the max on one side and the min on the other althoug the minimum

in this case is not going to be your problem that most times is failure to ignite the primer and therfire

failure to fire.

Depth probe is nr. 5 on this graphic.

Parts of the Vernier Caliper

![Image]()

The metal part must fit inside the bolt's head. Then when pushing the pin it must go into the slot but should not touch

nor push the gauge you just made.

This is different firearm but it will give you and idea of what a simple metal gauge should do....

B) Use the depth probe. Since you have to measure from the face of the bolt and the back end of the capliper will not go

into the recess of the bolt you have to make a reading first from the edge of the bolt (ring around the AR bolt lugs)

or there reset your caliper to zero. then close the bolt and push the pin against the bolt so it protrudes to the maximum

so now you can take a reading with the caliper again but the depth probe touching the pin. The trick here is since the pin

is round make sure the probe stays on the very tip of the pin and doesn't slide down.

In the below video, this is what this extension is for. It migrates the protrusion to a bushing that fits inside recessed bolts like the AR and it is also flat so it can simply measured w/o slipping off and angle errors. but my take you do not need it. The caliper alone should be able to do it.

Once you measure your protrusion you will know if this is the problem or you can discard this. but to me this is going to

be the issue. Also remember the AR pin must stop at the back of the pin (large ring) and hit the carrier there and not the taper int he tip of the pin.

Good luck.

A) Cut a gauge using a piece of steel. you can make the maximum as a square cut (Female slot).

Might be able to do this with a small file and where the back end of the caliper rail (depth probe) can fit.

You can make a thin rod and have the max on one side and the min on the other althoug the minimum

in this case is not going to be your problem that most times is failure to ignite the primer and therfire

failure to fire.

Depth probe is nr. 5 on this graphic.

Parts of the Vernier Caliper

The metal part must fit inside the bolt's head. Then when pushing the pin it must go into the slot but should not touch

nor push the gauge you just made.

This is different firearm but it will give you and idea of what a simple metal gauge should do....

B) Use the depth probe. Since you have to measure from the face of the bolt and the back end of the capliper will not go

into the recess of the bolt you have to make a reading first from the edge of the bolt (ring around the AR bolt lugs)

or there reset your caliper to zero. then close the bolt and push the pin against the bolt so it protrudes to the maximum

so now you can take a reading with the caliper again but the depth probe touching the pin. The trick here is since the pin

is round make sure the probe stays on the very tip of the pin and doesn't slide down.

In the below video, this is what this extension is for. It migrates the protrusion to a bushing that fits inside recessed bolts like the AR and it is also flat so it can simply measured w/o slipping off and angle errors. but my take you do not need it. The caliper alone should be able to do it.

Once you measure your protrusion you will know if this is the problem or you can discard this. but to me this is going to

be the issue. Also remember the AR pin must stop at the back of the pin (large ring) and hit the carrier there and not the taper int he tip of the pin.

Good luck.

Joined

·

77 Posts

Also noticed this the back end of the pin is showing deformation

Attachments

-

100.6 KB Views: 165

Joined

·

11,402 Posts

This is where the hammer hits. Some signs of wear are normal but not flat burrs.Also noticed this the back end of the pin is showing deformation

So this might be an example of a firing pin is not properly heat treated (hardened) or the wrong material or both and one could suspect wrong dimensions too.

Buy one firing pin from Armalite (if that is your bolt I would assume with AR10 system right?). don't interchange with other brands from who knows what mills and treatments. Specially don't interchange with other makers of different 308 systems even if they look similar. Unlike the AR15 there is no one single standard for parts.

Also I noticed this doesn't look like an AR10 firing pin. The AR10 is tapered and it has a spring. Are you sure you have an AR10 and not a DPMS or RRA upper? who built this upper again?

AR-10 FIRING PIN

Spring. (designed to minimize the risk of slam fires).

AR-10 FIRING PIN SPRING

Joined

·

11,402 Posts

Actually I can measure a firing pin for you if you want but it would be Stoner SR25/Knigths/DPMS type of system not AR10.

I think RRA might be using the same firing pin but not 100% sure.

I think RRA might be using the same firing pin but not 100% sure.

Joined

·

77 Posts

Asi as I uses their own bcg which they advised me not to replace with armalite parts when I bought it. I'm expecting a call from the boss at ASI tomorrow when he get back from some days off. Hopefully he can give me a definitive answer cause my head is spinning lolThis is where the hammer hits. Some signs of wear are normal but not flat burrs.

So this might be an example of a firing pin is not properly heat treated (hardened) or the wrong material or both and one could suspect wrong dimensions too.

Buy one firing pin from Armalite (if that is your bolt I would assume with AR10 system right?). don't interchange with other brands from who knows what mills and treatments. Specially don't interchange with other makers of different 308 systems even if they look similar. Unlike the AR15 there is no one single standard for parts.

Also I noticed this doesn't look like an AR10 firing pin. The AR10 is tapered and it has a spring. Are you sure you have an AR10 and not a DPMS or RRA upper? who built this upper again?

![Image]()

AR-10 FIRING PIN

Spring. (designed to minimize the risk of slam fires).

![Image]()

AR-10 FIRING PIN SPRING

Joined

·

11,402 Posts

For what I read from accuracy systems they use armalite carriers. Why they use a different pin I don't know. They might have a good reason.Asi as I uses their own bcg which they advised me not to replace with armalite parts when I bought it. I'm expecting a call from the boss at ASI tomorrow when he get back from some days off. Hopefully he can give me a definitive answer cause my head is spinning lol

But the pin head burrs you showed us are from a poorly hardened pin and I would not be surprised at all the protrusion is off as well.

Ask them what type of pin they use. Nobody uses proprietary pins.

I am sure they will make it right.

Firing pin must be replaced as it is damaged. Check also the spring for the pin.The firing pin definetly needs replacing at this point though no?

Joined

·

77 Posts

This what they told me when I noticed it said that on my invoiceFor what I read from accuracy systems they use armalite carriers. Why they use a different pin I don't know. They might have a good reason.

But the pin head burrs you showed us are from a poorly hardened pin and I would not be surprised at all the protrusion is off as well.

Ask them what type of pin they use. Nobody uses proprietary pins.

I am sure they will make it right.

Attachments

-

72.8 KB Views: 125

Joined

·

77 Posts

Well I was hoping I wouldn't but I'm sending the rifle back to Colorado to have it checked out by ASI . Let's hope the turnaround is fast.

Joined

·

1,430 Posts

I think that's a wise choice, I'd send some of those fired cases with it as well. Hope you get her back quick and running like a clock!Well I was hoping I wouldn't but I'm sending the rifle back to Colorado to have it checked out by ASI . Let's hope the turnaround is fast.

Joined

·

77 Posts

I emailed him all the pictures, let's hope she comes back quick and doesn't cost me anything! HahaI think that's a wise choice, I'd send some of those fired cases with it as well. Hope you get her back quick and running like a clock!

Joined

·

11,402 Posts

I think it is just the firing pin. But they are a good shop and will make it right.I emailed him all the pictures, let's hope she comes back quick and doesn't cost me anything! Haha

hopefully will not take 8 months like Beretta or FN. lol.

Joined

·

11,402 Posts

Do you have a set of calipers? Before you send it can you measure the firing pin just o satisfy our curiosity?

Lenght...

Back to the pin stop...

diameter at the rear end..

diameter at the head...

you never mesured the protrusion did you?

I will measure a knights firing pin and we can compare.

Lenght...

Back to the pin stop...

diameter at the rear end..

diameter at the head...

you never mesured the protrusion did you?

I will measure a knights firing pin and we can compare.

Joined

·

2,650 Posts

Over pressure for what? Mil spec ammo does not need to meet SAAMI specs for chamber pressures, and some lots of M118LR are known for showing pressure signs in hot weather - the powder was temp sensitive. The picture is not completely clear, but that sure looks like an extractor smear on the case head, and you do not see that with SAAMI spec pressures in LC brass.I highly doubt that LC ammo is over pressured, first thing I'd do is have the headspace checked.

That being said, I do not think the pressure is what popped the primers - even with the extractor marks, the primer edge looks fairly rounded. I would say those were probably mildly overpressure, but the primer issue is probably related to either a sharp edge on the pin or excess protusion.

I might be missing something though, how is excess headspace responsible for either popped primers or pressure signs on fired brass?

Joined

·

1,430 Posts

I'm no expert so don't take what I say as anything other then a joe's opinion, other's here know more then I. From what I have read and have been explained is too much headspace can cause pierced primers. When the firing pin hits the primer it shoves the case forward in the chamber, as the gases expand the case it will be gripped by the chamber starting at the front of the case where it's the thinnest. The primer starts backing out of the pocket until it slams into the firing pin and bolt or breech face, then the rear of the case will expand also slamming into bolt or breech face reseating the primer. The case will stretch at the web near the base of the case, the spot where we sometimes see case separation.Over pressure for what? Mil spec ammo does not need to meet SAAMI specs for chamber pressures, and some lots of M118LR are known for showing pressure signs in hot weather - the powder was temp sensitive. The picture is not completely clear, but that sure looks like an extractor smear on the case head, and you do not see that with SAAMI spec pressures in LC brass.

That being said, I do not think the pressure is what popped the primers - even with the extractor marks, the primer edge looks fairly rounded. I would say those were probably mildly overpressure, but the primer issue is probably related to either a sharp edge on the pin or excess protusion.

I might be missing something though, how is excess headspace responsible for either popped primers or pressure signs on fired brass?

You saw what I did, the primers are not flatten, in fact still round at the edges. A mark from the extractor but I don't see brass flow into the extractor recess, so I don't see signs of excessive pressure. It may be a firing pin piercing the primers, it is messed up and needs to be replaced, but he also had a few failed to fire. If the firing pin protrusion is too long and the headspace is correct then I'd be surprised to see rounds that didn't fire, in the same outing with the same ammo. That's assuming they were light primer strikes that caused the fail to fire, I'd love to see those rounds that didn't fire, maybe the OP can post pics?

From what the OP told us and the pics he posted these are all clues, pieces of a puzzle and lead in a direction of what to check. As I said before, one of the things I'd check is the headspace, if it was me. But he's doing the right thing and letting the experts resolve the problem. I'm sure they will replace the firing pin then test fire the rifle, I hope they also don't assume that's all that's wrong with it from the info they get and send it back with out checking everything. If it was my rifle, I'd send some of those cases with the rifle and ask they also check the headspace. They can measure the fired cases, if they have expanded too much then they should check it.

21 - 40 of 70 Posts

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 1.3M

- members

- 19K

- Since

- 2008

A forum community dedicated to all New York firearm owners and enthusiasts. Come join the discussion about optics, hunting, gunsmithing, styles, reviews, accessories, classifieds, and more!